Compressors are basically sort of devices used for storage of atmospheric air that are too high in potential. This is usually used in pneumatic devices. By rotating the membrane this compresses air. The compressed air is then stored in a storage like tube section.To know more about the process of the air compressor, visit the VannDigit.

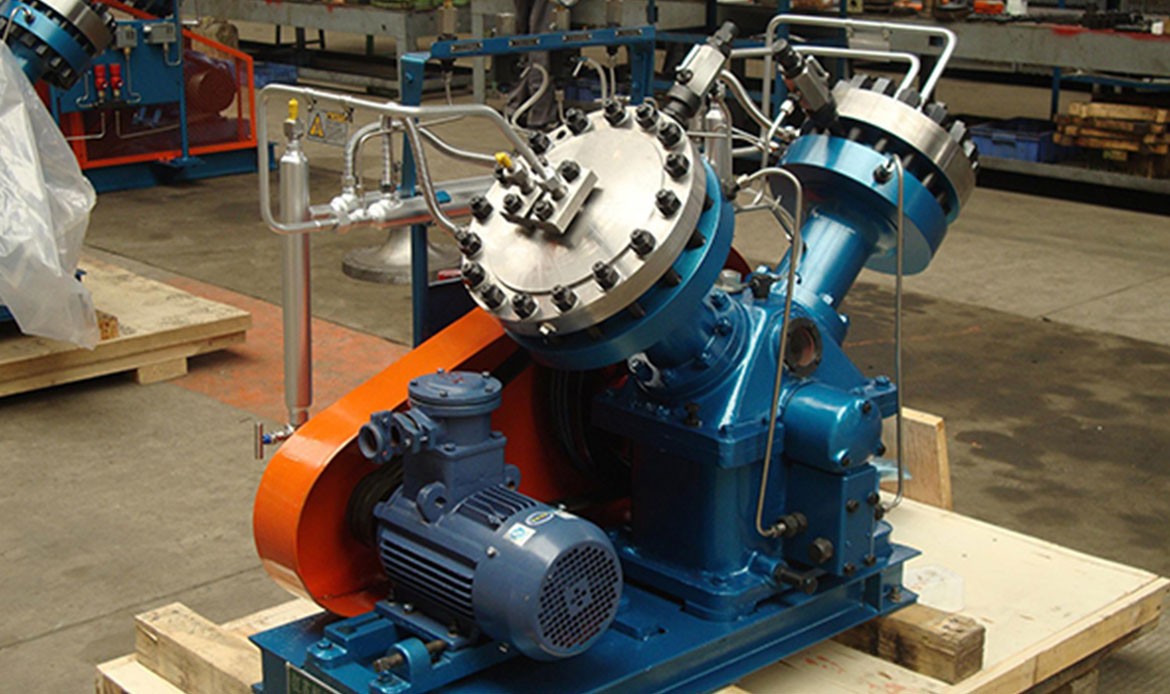

There is a hydraulic piston system in the diaphragm compressor which is designed in such a way that that bearings are removed and is well sealed, this is done so that the gas and the ionic liquids do not match. Many good manufactures like PDC Machines manufactures process gas compressors and other diaphragm gas compressors such as TFE and carbon monoxide compressors make quality diaphragm compressors. Membrane compressors is the other name given to these devices. CNC precision machining can provide ultra precise measurements on any sort of job and for any sort of product, part, etc. The more axes that the machine operates on the higher the results are for precision. Most of the time, the simplest precision capabilities comes from the CNC 5 axis machines. The cnc precision machining strategies explain by contour precision.

How Does a Generator Work? – The answer to that question starts with, “It depends!” It depends on the type of generator you’re speaking about. There are numerous types of generators. There are: Propane Generators, Diesel Generators, Wind Generators, Gas Generators, Natural Gas Generators and even Bio-Fuel Generators. Of course, there are probably some sources of generator power that I’ve missed. Generators that produce electricity operate on that same principle, just in reverse! Since I used a fan as an example, I’m going to spin things around and use a Wind Generator to explain this principle. This time we’re going to take the same fan and place it outside, not to provide a breeze, but to receive a breeze. As the wind blows, the blades on the fan turn. Attached to the blades is a shaft that goes into an electric generator motor. As this shaft attached to the motor turns, it produces electricity. Depending on the size of the generator, it may have just enough power to accommodate a small electric saw. Or, it can produce enough power to light up an entire hospital! Here you get the detail procedure about how do inverter generators work.

Diaphragm Compressor And its Components:

The Check Valves:

The check valves are indicated to coordinate the working conditions and the procedure gas. The valves are effectively available for investigation, fix or substitution.

The Hydraulic Inlet Check Valve:

This is for hydraulic fluid inlet check valves.

The Hydraulic pistons:

Cylinder is to pressurize the stomach. For higher weights, a cylinder without a ring, without pressing, acclimates to the arrival to a solidified and honed sleeve.

Hydraulic valves over pump:

It controls the weight in the pressure driven framework. The joined development of the stem, ball, and spring decides the weight scope of the valve.

The glass for over pump site:

This is the glass cover through which we can see the hydraulic fluid.

The injection pump Hydraulic:

This is run by the crankshaft, the pump provides the fluid in the hydraulic system.

The working of Diaphragm Compressors:

The diaphragm compressor comprises 2 frameworks, a hydraulic framework and a pneumatic force framework. Metal diaphragm is a defensive segment between the two systems. The pneumatic force framework comprises 3 diaphragm metal plates which are sandwiched between two plate depressions, air info and yield forms.

Hydraulic crankshaft engine control framework that moves the cylinder in low weight. The exchange of this cylinder manages the hydraulic liquid inverse to bring down the side piece of the diaphragm, the depression swing causes an adjustment noticeable all around procedure.

A few segments of the hydraulic framework can consequently fill the siphon, hydraulic liquid valve and air hydraulic valve that siphons overabundance air. To guarantee that the hydraulic framework consistently meets the weight revolution, the programmed filling siphon sends quick fisherman in the hydraulic framework after the compressor is killed. When there is a compressive power on the principle cylinder, the check valve shields the hydraulic framework from the programmed filler siphon, in this way a weight sponsor can be created in a framework that restricts the hydraulic siphon valve.

How Are Dc (Diaphragm Compressors) Valuable?

The diaphragm comes with many benefits and uses, it provides a void oil pressure because of the hermetic partition among gas and oil chamber, Scraped area free pressure because of static seals in the gas stream, Programmed shutdown if there should arise an occurrence of a diaphragm disappointment forestalls harm and this also has the capacity to release pressure till 3000 bar.